Two-tone coating

For a special aesthetic appeal in powder coating

Different colours on the same workpiece

AGRU also coats profiles in a two-tone design (double coating). The advantage of this special coating is that profiles that have already been rolled together with a plastic bar can be subsequently given a two-tone design. The following combinations are possible: Anodising/two-tone anodising and powder coating/two-tone powder coating.

Pre-anodising

The best base for powder coating

For aluminium parts

Pre-anodising and powder coating enable highly corrosion-resistant aluminium finished products. We recommend pre-anodising for parts that are installed near the coast (spray mist from salt water), in road or tunnel construction (gritting mist) and in indoor swimming pool construction work (higher chemical load in the atmosphere). Pre-anodising helps to prevent filiform corrosion in a better way. The result is excellent priming, while the aluminium remains electrically conductive for downstream powder coating.

Chromating

Unique corrosion protection

What does chromating mean?

Chromate layers on aluminium and galvanised steel act as a base for bonding the powder coating, while providing corrosion protection at the same time. The pre-treatment process originates from the automotive industry, where particularly high demands are placed on corrosion protection. The yellow chromate coating with hexavalent chromium which we use for aluminium is considered to be the most durable and to have the highest quality.

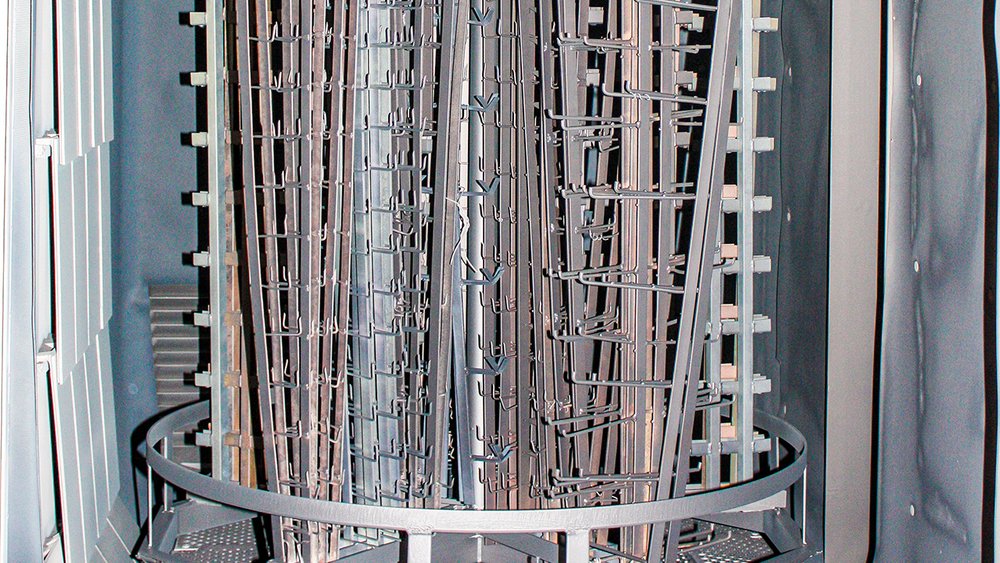

Steel shot blasting

Removes scale, paint and rust

Stainless steel shot ensures a perfect finish

Blasting is an abrasive surface treatment in which impurities such as scale, paint and rust are removed by the mechanical action of steel shot. Steel shot blasting provides the finish at the same time. It creates a uniformly rough surface, which is the ideal substrate for downstream powder coating.

Paint removal

Paint removal contracting on request from customer

Suitable for painted or powder-coating components

Old or no longer usable paint or powder coatings are removed from the component either chemically or thermally (possible for steel). Chemical paint stripping of the powder coating, paint or other special coating can be carried out in full (paint and primer) or selectively (the primer is retained), depending on customer requirements. If required, further pre-treatment can be carried out in the steel shot blasting system or chromating system.

Pickling

To achieve oxide-free surfaces

The first step in the coating process

In our pickling plant, we chemically remove existing paint and protective coatings as well as old or no longer usable anodised layers from the component. Alkaline paint strippers must not be used on galvanised workpieces or aluminium as this would damage the material. This is why they are pickled in a mixture of nitric acid and hydrofluoric acid. The process is fully automated and in compliance with applicable environmental standards.

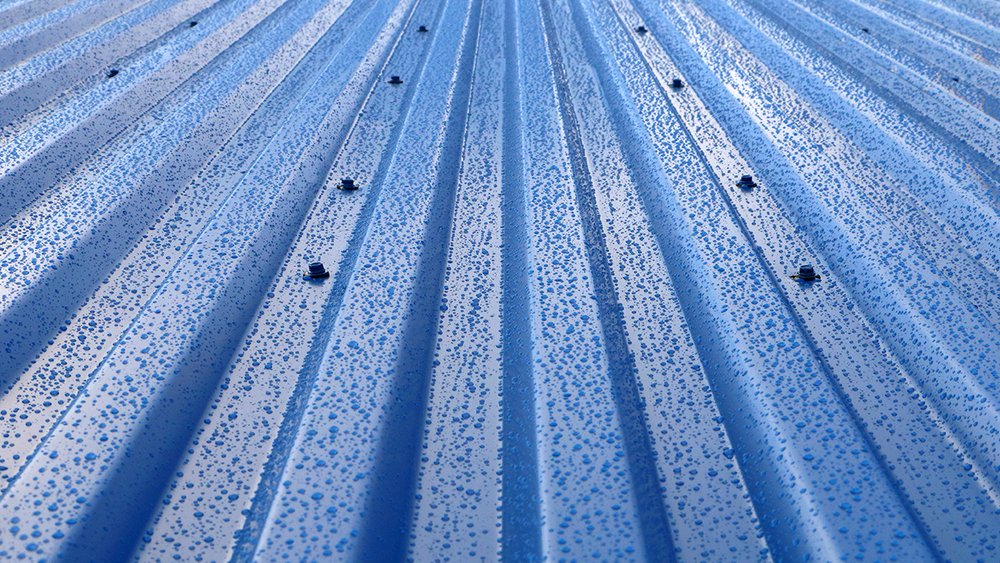

Noise suppression

Noise suppression coating stops noise

Coating for noise suppression of sheet metal

Uninsulated roofing made of trapezoidal sheet metal and metal structures can amplify the sound of pattering rain or ambient noise to an unpleasant boom. Noise suppression coating offers very good acoustic insulation values. It can be applied to galvanised sheet steel and primed aluminium. This special coating is applied to the rear side of sheet metal facade elements to reduce noise.

Foiling

Protective films for sensitive surfaces

Surface protection avoids costs and trouble

Sensitive surfaces need protection. To do this, AGRU Oberflächentechnik protects the finished parts by applying special protective films on request. The films can be removed without a trace after installation. Avoid additional costs and trouble and let our protective films provide effective surface protection for your workpieces.

Wrapping

Safe non-returnable packaging made of film wrap

Perfect protection during transportation

Your products are exposed to great stress during transportation. Thanks to our special non-returnable foam packaging, which is wrapped by hand, your valuable products are always optimally protected during shipping. Foam materials prevent damage caused by excessive pressure and vibrations.