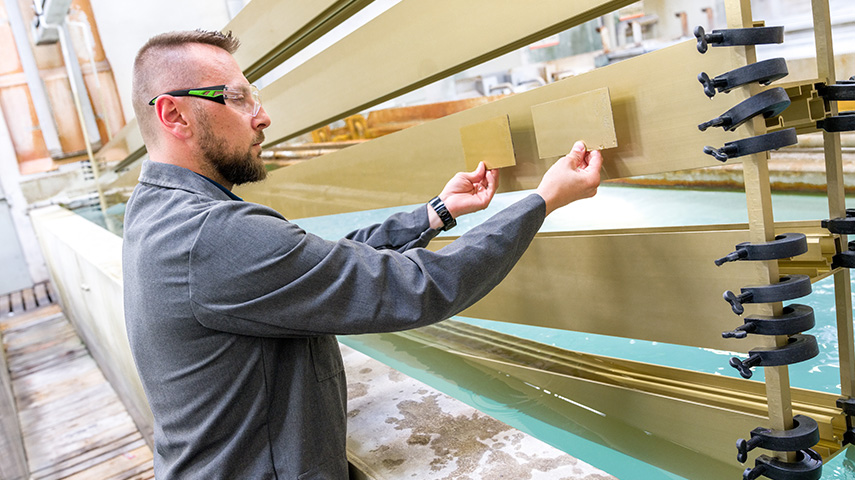

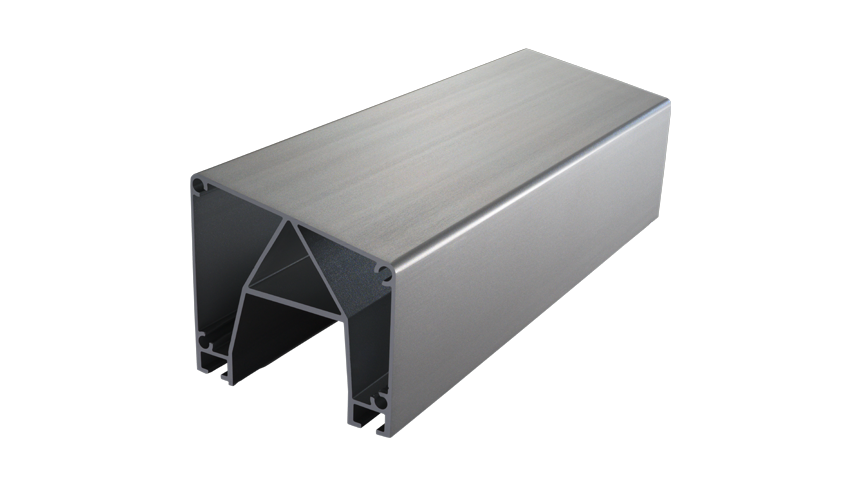

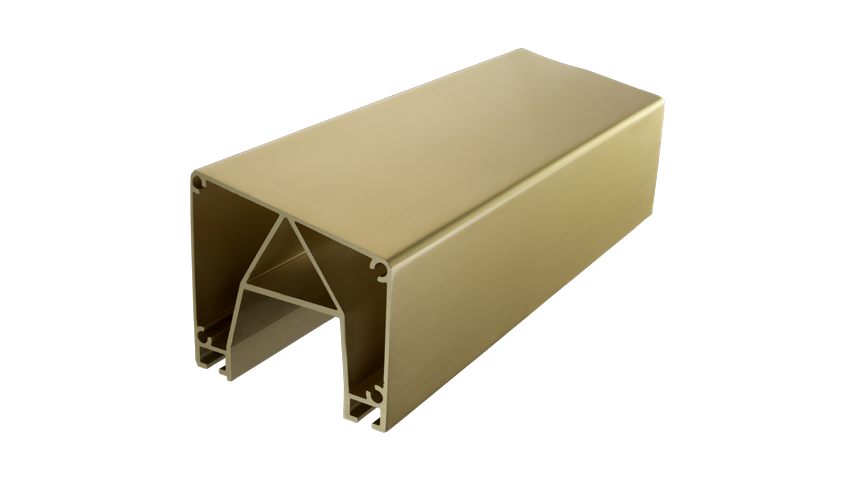

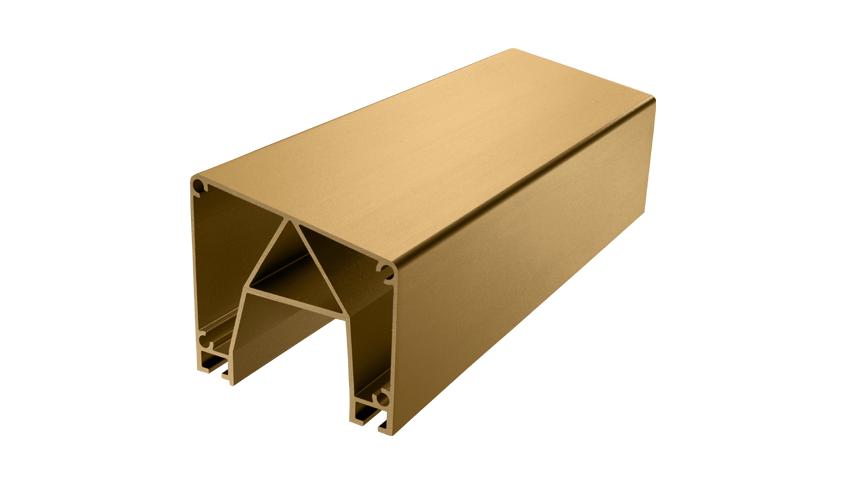

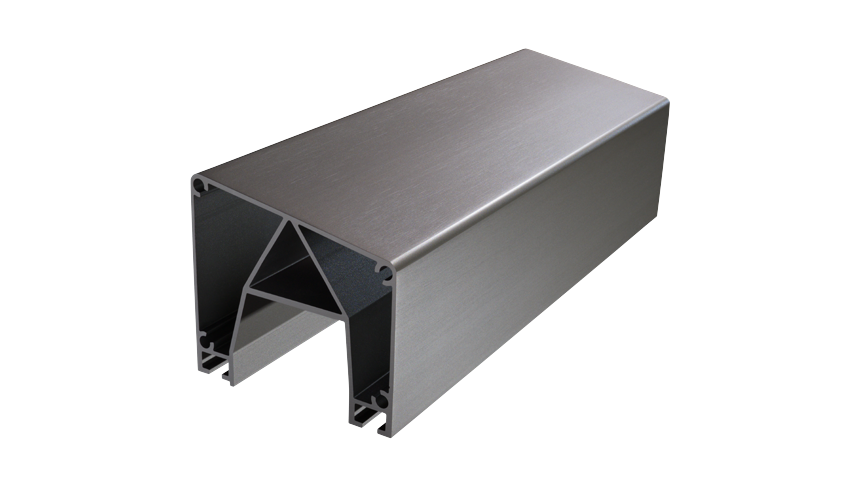

Surfaces

Different pre-treatments, whether mechanical or chemical, allow us to finish the surface of the aluminium in various decorative or functional looks. We follow the specifications of ÖNORM C2531 and/or DIN 17611 here:

E0

Without chemical or mechanical pre-treatment. Is used for technical applications to affect (or to only minimally affect) the dimensions of fittings and threads, for example. Sample inspection is essential for very high-precision parts, as there are only rough rules of thumb for this!

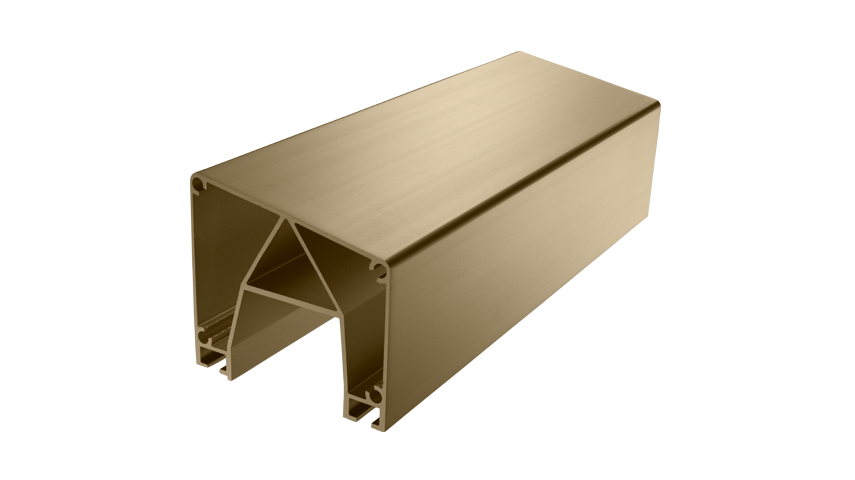

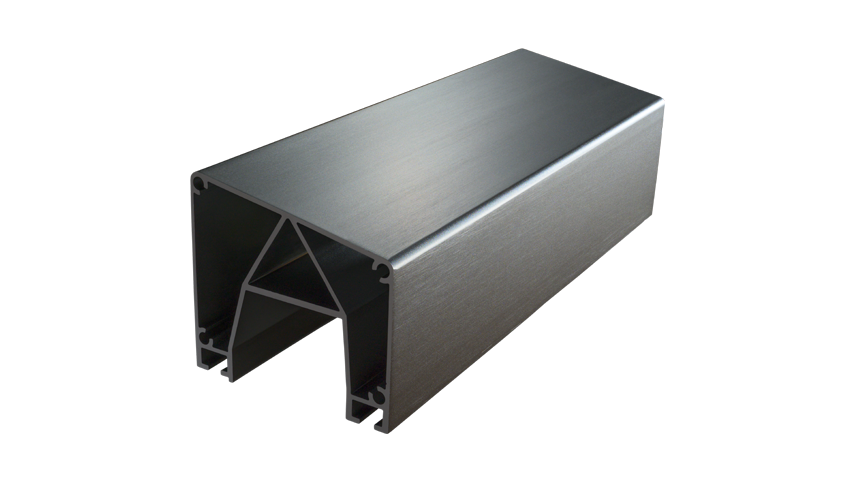

E1 Ground

The parts are ground and anodised. The result is an attractive, metallic-looking surface with visible grinding strokes. If lightly dyed in bronze, this results in the well-known and popular “Stainless steel look”. Material defects are removed for the greater part.

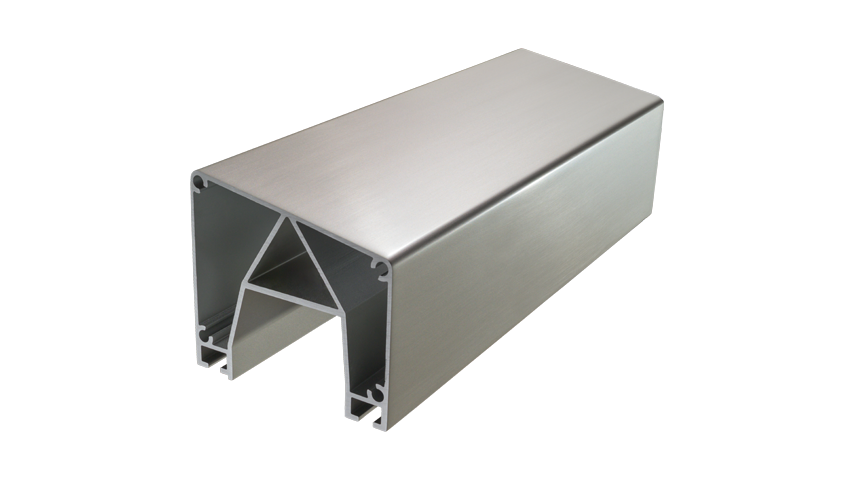

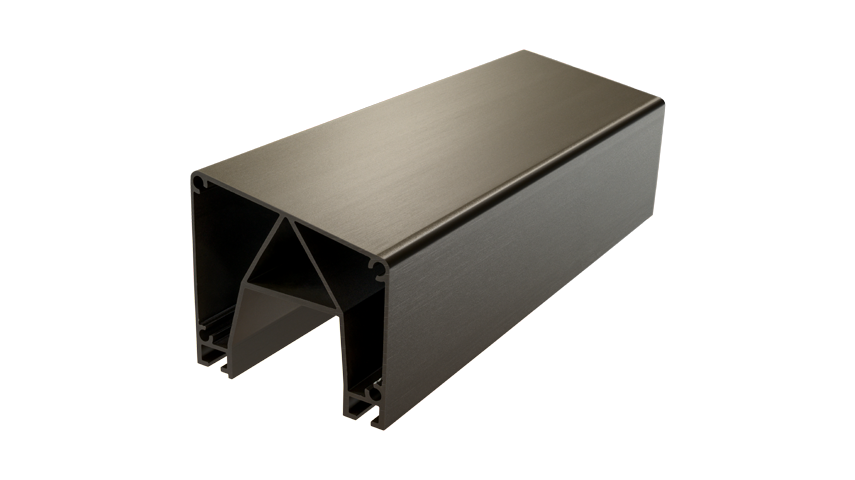

E2 Brushed

The parts are brushed and anodised. This achieves a light glossy look with brush strokes. Here too, an attractive “Stainless steel look” can be achieved with a slight bronze tint. However, there are restrictions to the material defects which are removed.

E3 Polished

The surface is polished and anodised. This results in a glossy finish. However, the material defects remain visible.

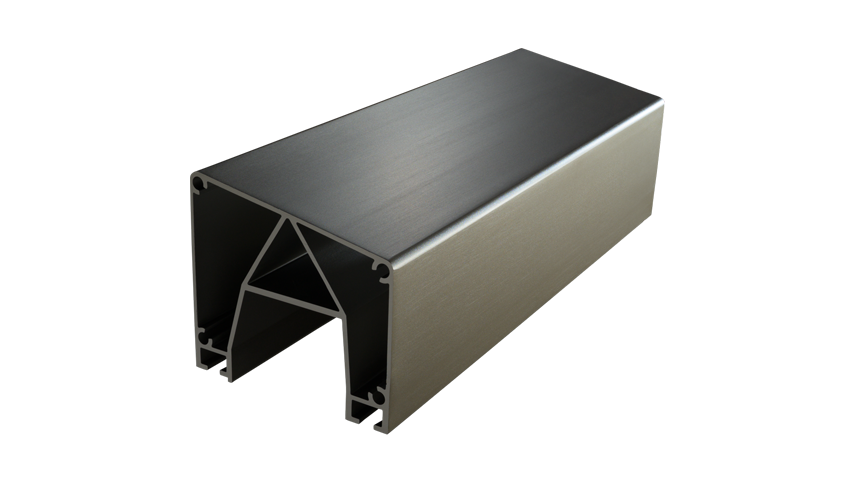

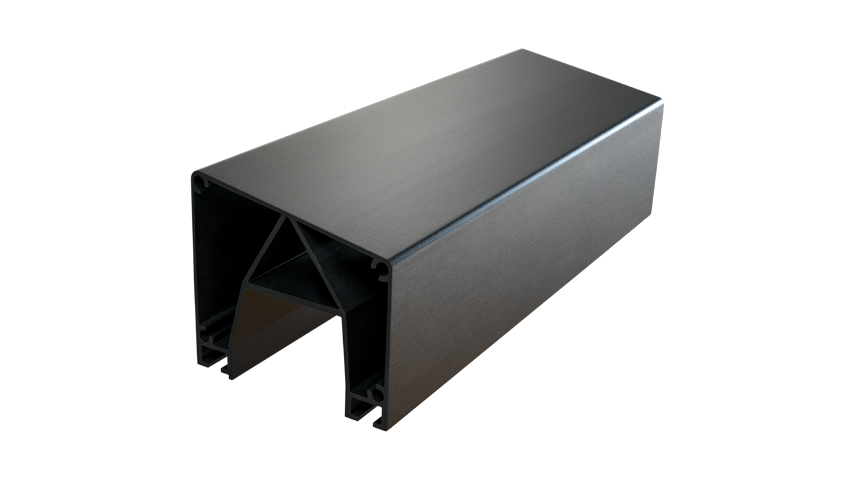

E4 Ground and brushed

If there are defects in the material, such as scratches, scuff marks or corrosion, etc., a perfect finish can be achieved using this treatment by grinding first. The finish itself is identical to E2 Brushed. The surface is slightly glossy and with visible brush strokes.

E5 Ground, brushed and polished

Probably the most sophisticated and also the most expensive surface finish. The finish is glossy with brush marks visible in part. Material defects are removed for the greater part.